What kind of screw extruder does pp T-Grip be produced by?

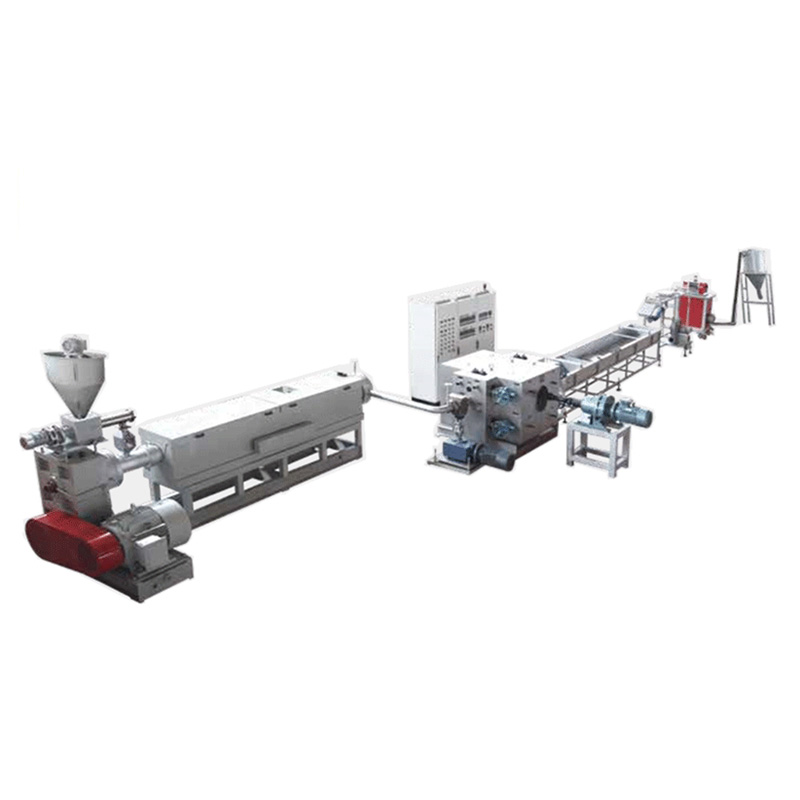

Have you ever wondered exactly how PP T-Grip, which can be widely used for plumbing piping and work installations, is produced? Well, it really is produced through a process called screw extrusion. The material that is plastic heated and forced through a screw extruder, ensuing in a last product that is strong, durable, and efficient in this process.

Great things about Using Screw Extruder for PP T-Grip Production

Certainly one of the significant top features of using a screw extruder for PP T-Grip production is its efficiency. Unlike other production techniques that need numerous actions and a large amount of time, screw extrusion produces the product this is certainly final a step that is single reducing the production time and cost. Additionally, the process creates products with precise dimensions and forms which are uniform which are essential for accurate fittings and installations.

Innovation in Screw Extruder Technology

Recent innovations in screw extruder technology have actually made the production process more cost-effective and efficient. For instance, the usage of modern materials that resist high conditions and wear has improved the durability of the extruder screw, reducing downtime and upkeep expenses. Also, advances in control systems have improved the persistence and accuracy of the screw extrusion process.

Safety Considerations in Screw Extrusion

Screw extrusion is a process this is certainly safe proper safety measures are put in spot. Several of the safety measures include making sure all going parts are adequately guarded, providing air flow that is adequate decrease the threat of breathing of harmful fumes, and ensuring that operators are well-trained to run the machinery safely.

Using PP T-Grip

PP T-Grip is oftentimes used for piping and plumbing installments due to its energy, durability, and simplicity of use. The twin screw machine hold is created to fit snugly onto pipes, ensuring a connection that is leak-proof. Also, it can be easily set up using hand that is easy, making it suitable for both professional technicians and DIY enthusiasts.

Exactly how to Make Use Of PP T-Grip

Using PP T-Grip is a process that is not difficult involves slipping the hold over a pipe and tightening it with a wrench. The hold is made to fit snugly on the offer and pipe a connection that is leak-proof. It is extremely important to make sure that the pipe surface is clean and free of debris before setting up the T-Grip.

Service and Quality

At our company, we pride ourselves on supplying screw that is high-quality designed to produce top-quality PP T-Grip. Our extruders are formulated from durable and robust materials to ensure performance that is lasting downtime that is minimal. Additionally, we offer exceptional service and support to our clients, making sure they will have the most out of our products.

Applications of PP T-Grip

PP T-Grip and single screw extruder machine has a range this is certainly wide of in piping and plumbing installations. Its commonly used in residential, commercial, and installments that are industrial pipes that are connect fittings firmly. Furthermore, it really is suitable for usage in applications that require resistance to chemicals and temperatures that are high making it ideal for usage in harsh surroundings.

Creating PP T-Grip screw that is using is a cost-effective, efficient, and safe way to getting top-quality products. The process is even more effective, accurate, and reliable, making it an excellent option for producing PP T-Grip with the recent advancements in screw extruder technology.

Comments

Post a Comment