Automobile air pipe blow molding machine

As our globe continues to evolve, we're constantly on the search for brand new and methods are innovative make things better, safer, and easier. The automobile industry is not any exclusion, and one among the latest innovations that waves which can be making the Automobile Air Pipe Blow Molding Machine. This piece this is amazing of has revolutionized the way air pipes are manufactured, and has ver quickly become a must-have for any automobile manufacturer. , we'll explore the advantages, innovation, safety, usage, service, quality, and application of the Automobile Air Pipe Blow Molding Machine.

Advantages of the Automobile Air Pipe Blow Molding Machine

The Automobile Air Pipe Blow Molding Machine has advantages that are many traditional types of air pipe production. Firstly, it really is considerably faster. The machine can produce up to 20 air pipes each minute, in comparison to the pipes that are 2-3 moment produced by conventional practices. Which means that production time is significantly paid off, and more pipes can be produced in a smaller period of time.

Next, the machine creates air pipes being of greater quality. The pipes are seamless and haven't any joins or seams, which means they've been less likely to want to leak. In addition, the machine creates air pipes that have a shape this is constant size, helping to make sure they are more straightforward to install.

Thirdly, the pipe machines is more cost-effective in the run this is very long. Although the cost this is initial of machine could be high, it quickly will pay for it self in terms of increased production and paid off labor expenses.

Innovation of the Automobile Air Pipe Blow Molding Machine

The Automobile Air Pipe Blow Molding Machine is an piece that innovative of the changed the real way air pipes are made. The machine utilizes a process called blow molding, involving melting plastic pellets and then blowing them into a mold to create a shape that hollow. This process is significantly faster and more effective than old-fashioned methods for air pipe production, which involves cutting and metal this is welding.

Safety of the Automobile Air Pipe Blow Molding Machine

Safety is a concern that top it comes down down to automobile manufacturing, and the Automobile Air Pipe Blow Molding Machine is not any exclusion. The machine is made with safety features that counter accidents and accidents. For instance, the machine has a safety interlock system that stops it from running if any safety guards are available or eliminated. In addition, the machine has an crisis end switch that can quickly be used to shut the machine down in the occasion of an crisis.

Usage of the Automobile Air Pipe Blow Molding Machine

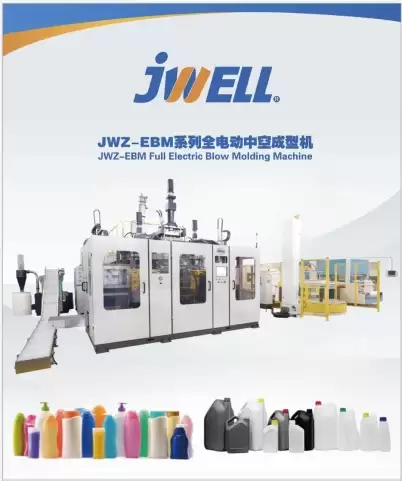

The Automobile Air Pipe Blow Molding Machine and JWELL corrugated pipe extrusion machine manufacturer is used to make air pipes being used in cars. These pipes are accountable for holding air to various parts of the engine car, such as for example for instance the motor and the brakes. The machine is straightforward to utilize, and requires training that minimal. The operator merely loads plastic pellets into the machine, sets the machine to the desired settings, and presses commence to utilize the machine.

Utilizing the Automobile Air Pipe Blow Molding Machine

To work well with the Automobile Air Pipe Blow Molding Machine, follow these actions which are easy

1. Load the plastic pellets into the machine.

2. Set the machine to the desired heat.

3. Set the machine to the desired settings, such as for instance for instance the size and shape of the air pipe that fresh.

4. Press begin.

5. Wait for the machine to accomplish.

6. eliminate the fresh air that completed from the machine.

Service and Quality of the Automobile Air Pipe Blow Molding Machine

The Automobile Air Pipe Blow Molding Machine is made to be simple to service and keep. The machine is manufactured out of high-quality materials which can be made to final, and it comes down with a warranty for added reassurance. In addition, the machine was created to generate air pipes of the quality that greatest, making sure they've been strong, durable, and lasting.

Application of the Automobile Air Pipe Blow Molding Machine

The Automobile Air Pipe Blow Molding Machine and DWC pipe extrusion line for the water pipe is used by automobile manufacturers around the globe. Its an piece this is important of this is used to produce air pipes for a range that wide of, from passenger cars to heavy-duty trucks. The machine can also be used by businesses that create other products which are plastic such as for instance for instance bottles and containers.

The Automobile Air Pipe Blow Molding Machine is an innovation that amazing has revolutionized the way air pipes are made for cars. With its advantages which are numerous you can easily realize why this machine has ver ver quickly become a must-have for any automobile manufacturer. It really is fast, efficient, safe, and creates air pipes of the quality this is greatest. This machine will wow whether you may be a manufacturer or a customer.

Comments

Post a Comment