What is the process flow of printed circuit assembly?

Printed Circuit Assembly (PCA) will be the method of manufacturing circuit this is certainly electronic by assembling electronic components as much as a printed circuit board (PCB). Its what makes our smart phones, tablets, laptops, as well as other products which can be electronic correctly. A PCB offers a platform where electronic elements is put and connected utilizing a movement of electrons through the printed paths within the board in easy terms.

Printed Circuit Assembly involves putting parts which are electronic a board that will help of their working, which is used to create electronics like laptop computers and smart phones. The board includes a set of pathways that enable electricity to flow through them, linking most of the components being electronic.

Printed Circuit Assembly means components and this can be putting a board that can help them work, like placing different components in a toy or building blocks to make a tower. These panels then become section of other devices which can be electronic.

Precisely how is Printed Circuit Assembly done?

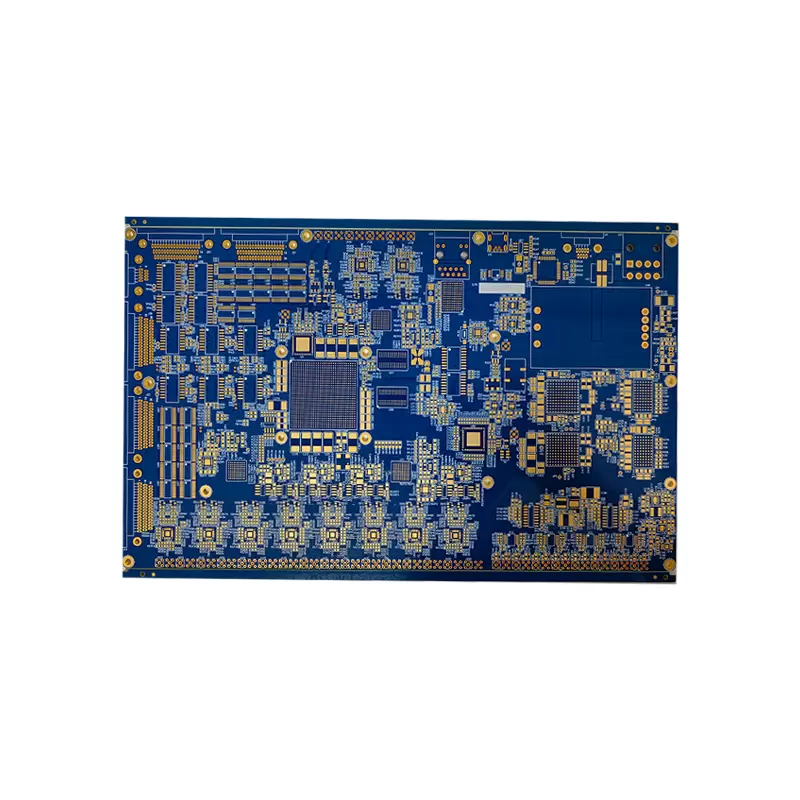

PCA involves a couple of actions, including design, manufacturing, and evaluating. The printed circuit antenna design procedure involves creating a design for the board and determining positioning that is component. Then, the boards are manufactured by etching the copper into the desired form, drilling holes for component placement, plating and publishing solder from the board, and mounting sun and rain. Finally, the board is tested to make certain that it functions correctly.

A board is first designed and presented to prepare where various electronic components is put to help make a Printed Circuit Assembly. The board is then made by shaping the copper and holes which can be adding the components and also other connections. The board is plated and printed with solder, then the right parts are added. Finally, the board is tested to test whether it's working precisely.

To make a Printed Circuit Assembly, we first make a plan of the best place to put components which are different the board. Then we make the board by shaping it and holes which are adding components to obtain in. We place parts concerning the board and connect them. Then we check if the board works properly.

Do you know the options that come with Printed Circuit Assembly?

The use of PCA has several benefits, including compactness, dependability, and cost-effectiveness. PCA allows products that are electronic become smaller, making them more portable. Additionally it is dependable since it minimizes the likelihood of loose connections and decreases the probability of electrical shorts. Moreover, it really is economical due to the fact need is paid off because of it for manual labor, that can easily be costly.

Printed Circuit Assembly and printed circuit board antennas offers benefits which is often numerous including smaller plus much more portable electronic products, enhanced dependability by reducing the likelihood of loose connections and electrical shorts, and cost-effectiveness by decreasing the cost of manual work.

Placing things along side Printed Circuit Assembly makes products smaller, more dependable, and cheaper. This means we could carry our devices around easier plus they are less likely to break.

Just how is Printed Circuit Assembly innovating?

PCA is continually progressing with innovations like Surface Mount tech (SMT) and 3D Printing. SMT involves changing through-hole elements with smaller, surface-mounted people. 3D Printing allows when it comes to creation of three-dimensional circuitry and elements, offering great design freedom and reducing the length of the final item having said that.

Printed Circuit Assembly is often being enhanced with innovations like Surface Mount tech, assisting to make the elements smaller, and 3D Printing, makes it possible for us to help make circuitry this is certainly three-dimensional components. This implies we are able to make devices smaller in accordance with better designs.

Printed Circuit Assembly gets better by making use of ideas which are new exterior Mount Technology to create things smaller, and 3D Printing to help with making parts in 3D and also make devices look better.

How come Safety Essential in Printed Circuit Assembly?

Security is critical in PCA because of voltages being high, the risk of handling hazardous materials, as well as the chance for PCB defects. The conductive pathways on PCBs carry electrical signals which could cause shock that is electric. Additionally, handling materials which are hazardous lead may cause health issues. The manufacturing of PCBs may result in defects sometimes within the PCBs, leading to circuit malfunctions or fires.

Safety is significant in printed circuit assembly because of high voltages that will cause shock that is electric dangerous materials like lead that could cause health conditions, although the likelihood of defects, ultimately causing fires or circuit malfunctions.

We should be safe in Printed Circuit Assembly because electricity can shock us, some materials like lead will make us ill, and sometimes the panels do not work right, which may cause fires.

Printed Circuit Assembly is crucial in to the manufacturing of gadgets, also it's constantly enhancing with new innovations. It is critical to ensure security in the process of Printed Circuit Assembly, therefore the advantages of the technology are worth the time and energy had a need to produce these devices.

Comments

Post a Comment