What effect does changing the outer diameter of the horizontal split case pump impeller have on the pump performance?

Hello, everyone! Today we are going to learn everything about pumps! There are very interesting machines which pump liquids from one place to another. That impulse is due to a crucial component within the pump referred to as the impeller. The impeller is essential to pump performance. This is significant because pumps are everywhere: in factories, in buildings, and even in our homes to transport water and other liquids. At Credo we build efficient and best-in-class pumps.

What is an Impeller?

But first, let’s figure out what an impeller is. The impeller is the revolving piece within a pump that causes the fluid to move. Same thing, if you think about a fan, you can visualize the impeller. It has curved blades, a bit like on a fan blade, which push the liquid in one direction or another. It assists the liquid to flow inside the pump smoothly. This is a key dimension of the impeller. The larger the impeller the wider it is across the blades at their widest point.

What Effect Size of Impeller has on Pump Performance

Next up, let's explain how the size of the impeller affect the performance of the pump. To assess this, we could examine two critical variables: flow and head. Flow horizontal split case pump means how much liquid the pump can move over a period of time. It’s like a river, so the larger the river, the more water that gets in that river.” Head is a measure of how high the pump can lift the fluid. For example, consider attempting to lift a bucket of water. If it’s too heavy, you may have difficulty getting it up high enough.

Importance of Impeller Size and Pump Efficiency

Well design, the size of the impeller, is very vital for the working of pump. This is known as efficiency. Efficiency informs you how well the pump converts power into kinetic energy of the liquid. An impeller that is too small means the pump has to work significantly harder to actually move the liquid. This indicates that it would be consuming more energy and is less effective. The harder the pump works, the quicker it can fail as well. A too big impeller might not even be able to move the liquid at all. Of course, this is also no good because it implies the pump is not performing its task properly.

Horizontal Split Case Pumps: Can You Change Impeller Diameter?

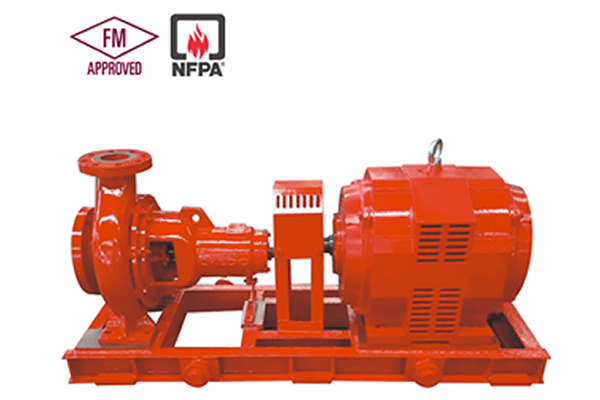

The size of the impeller within a hollow pump casing is large enough to allow substantial liquid bin flow. This horizontal fire pump is really important! By increasing the size of the impeller, the pump is able to move more liquid, which is desirable if we want to fill up a big tank quickly. But if the impeller is oversized, it may not be able to raise the liquid to the necessary height. Alternatively, by making the impeller small, the pump is capable of delivering the liquid to a greater height, which is useful if we want to transport the liquid to a greater height, such as at the top of the building. But with a smaller impeller, the pump is able to move less liquid at a time, so we have to find the right balance.

Head and Flow by Impeller Size

Now let’s examine how the size of the impeller affects the head and the flow. A larger impeller will increase the liquid flow rate, so more liquid can be pushed out by the pump in a shorter time. A larger impeller will, however, also increase internal resistance within the pump. That means the head, or the height at which the pump can raise the liquid, will decrease. To use an analogy: when you try to push a heavy box, the box is harder to lift when it is heavy. Minimize the impeller, the flow rate will drop, but the head will rise. The smaller impeller creates less resistance, which allows the pump to lift the liquid to a greater height.

Best Performance: The Right Impeller Size

In order to get the maximum performance from a horizontal split case fire pump, it is very critical to install the correct size impeller. Its size is determined by what we are pumping, and for what end purpose. If the impeller’s too small, then the pump may not be able to move enough liquid. This can become a problem when we need a lot of liquid fast. An impeller that is too large could cause the pump to draw too much energy or not perform optimally.

So, at Credo, we work with our customers to find them the right size impeller for the right job. We collaborate closely with them to find out what they are pumping and how they would like their pump to function things. It is our use of intelligent technology that makes for an energy-efficient impeller design. This reduces our customers' energy bills and contributes to the protection of the environment and reduction of waste.

So, in essence, the impeller size has huge bearing over efficiency of the pump in case of horizontal split case pump. Adjusting impeller size shows variation in pump head and flow. Selecting the correct size is vital to ensure the pump functions correctly and efficiently. From October 2023, we are training with data up. So that is pumps in a nutshell, thank you for reading along and learning with us today!

Comments

Post a Comment