The wire tube is connected to the junction box

How a Wire Tube is Connected to the Junction Box

Whenever a wire tube is connected to the junction box, it ensures safety. Besides, it also helps to organize and route cables in a neat and orderly manner.

The junction box is a metal or plastic box used to house wires and other electrical components. They are sized according to the number of conductors they can hold.

Conduit Body

A conduit body is an integral part of an electrical raceway system. It provides access inside the raceway for wire pulling, splicing and maintenance work. It can also facilitate changes in direction or allow more bends to be made within a conduit run.

Conduit bodies are available in different shapes and sizes to fit your system’s needs. The conduit fittings type of conduit body you use depends on the size and shape of your conduit run, as well as the number of conductors you need to connect together.

X Style Conduit Bodies are designed to provide easy access for wire pulling and splicing and are compatible with both IMC and Rigid conduit. They have a flat back design for mounting close to walls and include neoprene gaskets for extra resistance to moisture.

EMT Conduit Bodies

The most common type of conduit body is the EMT, or thin-wall, conduit. It is less expensive and lighter than galvanized rigid conduit (GRC). This type of conduit can be threaded, and it is commonly used in commercial and industrial buildings.

Another common type is intermediate metal conduit (IMC). It is heavier than EMT and may be threaded, but it is not as commonly used in residential applications.

The National Electric Code (NEC) requires that conduit bodies be sized appropriately to accommodate all conductors in a run. If the conduit is too small, it could overheat or damage conductors during pulling. The conduit body should be sized to provide enough room for each conductor to have a free space of at least eight times its trade diameter in the largest raceway it is connected to. This ensures the safety of all conductors. The NEC also states that a conduit body connected to more than one raceway must have a total length between its entries no less than 16 inches. If the NEC is followed, your wiring systems will be safe and will be able to function efficiently. This will save you time and money in the long run!

Wire Loom Tubing

Wire loom tubing is a type of conduit that is used to hold wires together and organize them into bundles. It also provides some protection against abrasion and environmental damage.

Its ridges and grooves help keep the bundles organized, and it can be used for a variety of applications. Its black polyethylene corrugated construction offers a high degree of strength and durability.

This type of conduit is typically used for wiring applications, such as in home theaters and security systems. It is easy to install and can protect the wires from abrasion, tripping hazards, and damage by water and debris.

The most common type of loom tubing is split wire loom, which has a slit down the side that allows you to easily insert your wires over a long run. When twisted or bent, the slit remains closed to prevent the wires from coming out.

You can find split wire loom tubing in a variety of colors and materials, including standard polyethylene, red, and high temperature rated nylon. It is suitable for automotive, marine, and industrial applications and is available in sizes up to 10 feet.

When running cables, it is important to make sure they are connected to the junction box. If the wires are not, it can cause overheating, short-circuiting, sparks, and fires.

If the wires are too close together, it can also cause electrical interference. The best way to avoid this is to separate the wires before connecting them together in a box.

A junction box contains hot (black), neutral (white), and grounding (green or copper) wires. Each pair of wires should be joined together using approved wire connectors, such as a wire nut.

A junction box can accommodate as many as six cables. However, if you are installing in an outdoor location, it is best to purchase a larger box to make sure your cables can fit comfortably.

Electrical Metal Tubing (EMT)

Electric metal tubing (EMT) is a type of conduit that protects electrical wires within buildings. This tubing is made from a variety of materials, such as steel and aluminum. It is often galvanized to resist corrosion.

EMT is used mainly in residential and commercial buildings. It's also a common choice for outdoor wiring due to its lightweight and easy-to-handle characteristics.

It's not recommended for every installation, though. Areas with a lot of traffic or chemical angle box fumes may be better off using a different conduit.

You can connect the tubing to the junction box by threaded connections or couplings. You can choose from a wide range of fittings and couplers to suit your project needs.

A fitting attaches to one end of the tube and allows you to turn it. You can use a sweep to make a slow turn or a pulling elbow to make a sharper turn.

The fittings can be either compression or set-screw. Compression fittings provide strong but not waterproof joints, while set-screw fitments provide concrete-tight joints.

Before connecting the tubing to the junction box, you will need to determine where the wires will go. Then, you will need to plan the route and make sure that the tubes are secure.

Once the conduit is firmly secured to the surface, you can run the cable. You can use a fish tape or wire lubricant to help you pull the cable through the tube.

You can also use an electrical bender to make bends in the conduit. These tools are available at many home improvement stores and can save you a lot of time.

Conduit can also serve as a grounding path for circuits in your building. It is important to ensure that all your connections are firm, or your grounding path could break.

A common tip when bending the conduit is to buy pulling ells, which allow you to easily turn inside corners without wasting time. You can also buy pre-bent 90- and 45-degree angles that are connected to straight sections of EMT with couplings. This will save you a lot of time and will ensure that you'll be able to turn the inside corners and change direction with ease.

Flexible Metal Conduit (FMC)

Conduit tubing is an electrical wire duct that protects the wiring from fires, mechanical damage and corrosion. It can be made out of many different materials, including metal, plastic and calcined clay.

A flexible metal conduit (FMC) is a type of wire tube that is connected to a junction box, typically at the end of a run of cable. It is usually used when it would be difficult to use an EMT or other non-flexible conduit in a given installation, such as in dry areas where metallic strength is required to protect the conductors inside.

FMC is a helical coil of a self-interlocked strip of aluminum or steel that forms a hollow tube through which wires can be pulled. It can flex freely and can be cut to length using a flex conduit cutter.

The helical coils of the FMC are also able to snake through walls and other structures. This extension tee box makes the tubing useful in a variety of installations, from underground parking garages to buildings.

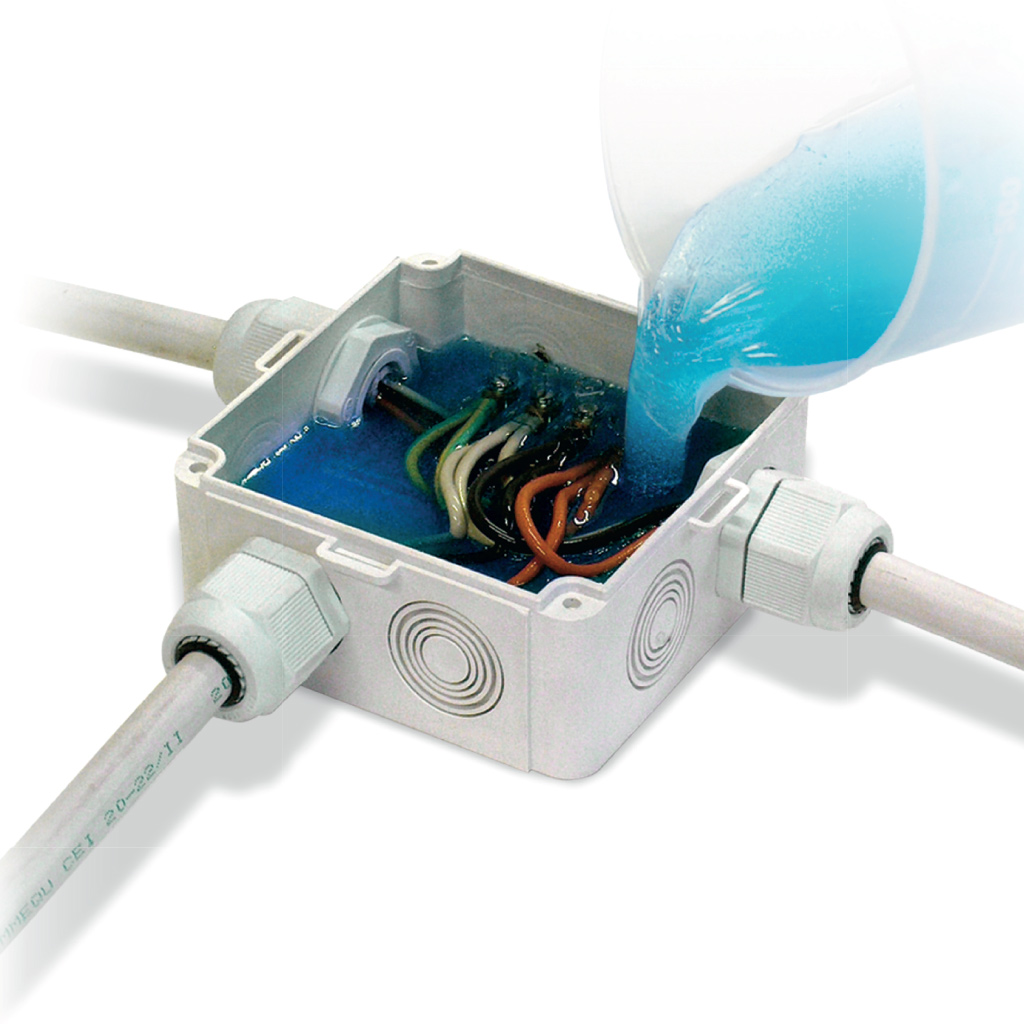

There are several types of flex conduit, all of which are designed to protect electrical wires. One is called a liquidtight flexible metal conduit (LFMC). This conduit is encased in a plastic sheath that gives it water-resistant protection.

Another type of flex conduit is the extra-flexible type, which is made from high-grade galvanized steel and is more resistant to corrosion than other conduits. AFC offers two types of extra-flexible conduit: Full Wall and Reduced Wall.

These conduits are UL-listed, meaning they meet the National Electrical Code (NEC). They are also approved for use as equipment grounding conductors.

Unlike the other types of conduits, flexible metal conduit is not insulated and does not have the insulated wires pre-installed in it. This means that it requires more work, but it is more convenient than MC cable.

In addition, the NEC permits longer runs of flex conduit with certain limitations. It allows a recognized equipment grounding conductor and the conduit and fittings to be listed for grounding, but it limits the length to 6 ft.

Depending on the situation, you may need to re-do some of your wiring and connect the conduit to a new junction box or pigtails. This can be a frustrating process, but it is essential to avoid accidents and ensure safety.

Comments

Post a Comment