What are the features of the junction box?

What Are the Functions of the Closed Junction Box?

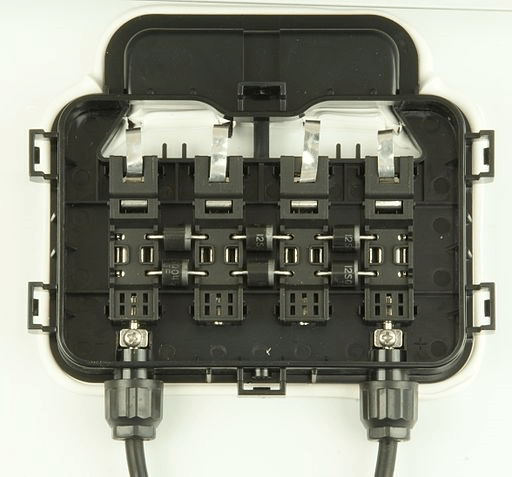

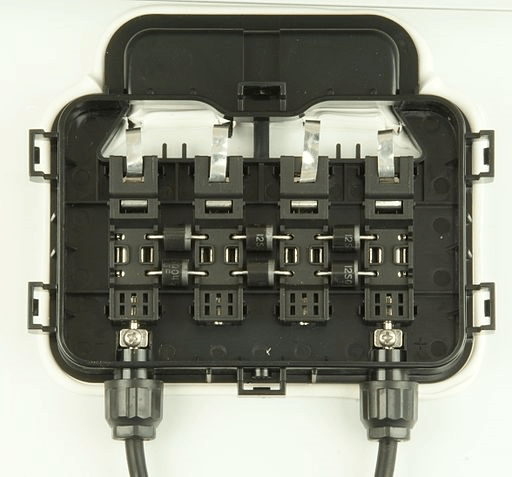

The closed junction box is a type of electrical enclosure that houses the electrical connections that allow wires to be joined together. They are available in different sizes and shapes.

These boxes are a good way to keep the wires inside safe from any weather conditions. They are also a good safety measure that can reduce the chances of sparks and fires.

Functions

Junction boxes house and protect electrical wires that are connected before they go to their outlets or switches. The boxes are usually made of metal or plastic, and they come in a variety of sizes and types.

Most home and commercial wiring connections need to be made inside a junction box for safety reasons. Leaving loose wire connections exposed can cause overheating, short-circuiting, sparks, and fires. It’s also easier to fix a problem when all the connections are in one place and the wiring is protected from the weather.

The closed junction box also provides protection from vandalism, something that’s more common than you may think. These boxes are often made from hardy materials and can be locked for added security.

They’re usually made to be able to accommodate a lot of wiring, so they’re a good choice for residential properties. They’re available in a variety of shapes and sizes and can be installed inside or outside.

Some types of junction boxes are designed for specific uses, such as for ceilings or other interior spaces. These boxes are usually a little bigger than standard ones, and they’re shaped to be able to fit more wiring without compromising their functionality or structural integrity.

Typically, these boxes are rectangular or octagonal in shape and can fit a lot of wiring in them. They’re a great option for homes that have large spaces, and they’re often available in colors that match the walls.

The most important function of a junction box is to protect the wires from the elements. They’re waterproof, so they’re a great choice for outdoor locations where the wires are likely to become damaged by rain or other natural forces.

These boxes also prevent people from being shocked by the wires if they touch them accidentally. This terminal box is especially true in residential settings, where children and other unsupervised individuals might play near a wire.

These boxes are an essential part of a building’s electrical wiring system, and they’re usually made from metal or plastic. They’re available in a varietyof sizes and types, and they can be easily installed to provide additional safety for your home or business.

Materials

The closed junction box is a metal or plastic enclosure that houses one or more wiring connections (known as branch circuits). They also protect the wiring from the elements, unwanted contact, and tampering.

These boxes come in various sizes to meet the demands of different projects and applications. Some are small enough to fit inside a cupboard or closet, while others can be fitted into walls and ceilings.

A closed junction box is usually sized according to how many wires it can hold, so make sure you select the right size for the job at hand. You don’t want to overload the enclosure, and an overstuffed box can be a fire hazard.

Most closed junction boxes are rated by NEMA and/or IP scales to ensure they can withstand certain environmental conditions. If you’re building a marine vessel, for instance, you might need to choose an enclosure that’s rated for ingress protection in extreme weather conditions like sea breezes and corrosive salt water.

Commercial environments such as warehouses, distribution centers and manufacturing plants require junction boxes that can handle the rigors of industrial operation. These facilities use a lot of electricity to power lighting, climate control and other essentials. They often have numerous splice points, so they need a robust build to resist the effects of impact and other factors.

The most common materials used in electrical enclosures are metal and polymers, each of which offers different properties. For example, ABS is a non-metal material that has a good resistance to heat, chemical corrosion and oxidation. Fiberglass is another type of plastic that’s resistant to a variety of caustics and harsh environments.

If you need a sturdy and resilient closed junction box for an outdoor application, the AN Series aluminum enclosures from Polycase are an ideal choice. They are rated up to NEMA 6P for superior performance in challenging commercial environments, and feature knockouts that make it simple to customize your configuration.

Ultimately, the materials used in a closed junction box are just as important as its overall design and function. Choosing the right material is essential for ensuring that your project will last for years to come.

Sizes

A closed junction box encloses wire connections in a safe way, which helps protect against short circuits and other electrical problems that can lead to fires. These boxes are also essential for building codes, and they come in many different shapes and sizes to suit your needs.

These boxes are made of metal or plastic and can be found for cheap prices at many hardware stores. They're often used in a variety of electrical applications, including installing light fixtures, and as switches or receptacles when matched with the proper cover plates.

They're available in a range of styles and depths, with some models accommodating one to six gangs. This allows electricians to create the right configuration for a specific project.

Some junction boxes are designed for installation to drywall, while others are made of metal and fasten to a surface with a "heel" or "ears" that make them easy to install without having to cut holes in the wall or floor. In these cases, you'll want to use a box extender, which slides over the opening of the box and adjusts as needed to fill in the gap between the wall and the junction box.

Typically, these types of boxes are installed during new construction to support wiring devices and splices. However, they can also be used in older structures for convenient outlets or switches.

For commercial electrical applications, a junction box needs to withstand the elements and accommodate large numbers of connections. This intersection box requires an impact-resistant build, enough space to fit a variety of conductors and wiring devices and a UL 94 flame rating that protects against open flames.

In marine applications, such as cargo ports, marinas and seafaring vessels, junction boxes need to withstand waves, wind, corrosive salt water and possibly even submersion. The best type of enclosure for these environments is one that has an IP68, IP67 or IP65 protection class.

These are some of the most common sizes of the closed junction box, and they're suitable for a wide range of applications. They can also be used for a variety of industrial wiring projects, and they're commonly found in warehouses, DCs and other large facilities.

Installation

A closed junction box is an electrical enclosure that contains wiring. It is designed to be installed in a specific area of a wall, usually to split off power from a single source into multiple outlets or switches.

It encloses wire connections and prevents damage from a short circuit or sparks from igniting flammable materials nearby. It is also an important safety component for a building to meet electric code requirements.

Choosing the correct junction box is important for many applications, including warehouses and distribution centers. These extension tee box areas often use a lot of electricity to power lighting, climate control and other essentials.

For example, an outdoor warehouse may require a NEMA 1 enclosure to protect its electronics from harsh weather conditions. Alternatively, an indoor distribution center might be able to get away with a NEMA 12 enclosure.

The size of a junction box is determined by the number of wires entering it. Multiply the total by 2 if the wires are 14-gauge, or add 2.25 if they are 12-gauge.

You can also buy a separate ground wire, which you'll need to connect to the box's ground screw. This ground wire should be either green or copper-colored.

Installing a closed junction box is a simple task that anyone can do with the right tools and supplies. Just make sure you follow the instructions and take the proper precautions when working with electricity.

First, strip the ends of all wires that will be in the box. This will allow you to fit all of the wires into it without them being too short or twisted. You can then push them all into the box, and secure it with screws to hold it in place.

Once you've finished, turn on the power and test your work to ensure it's done properly. If you notice any problems, contact a professional to correct it.

Whether you're completing an electrical job or replacing the switch on your ceiling fan, installing a junction box is necessary to keep you and other people safe. Electricians will be able to correctly splice the wires and seal them in the box, protecting the wiring from damage, sparks and possible fires.

Comments

Post a Comment