What are the functions of the closed junction box

What Are the Features of the Junction Box?

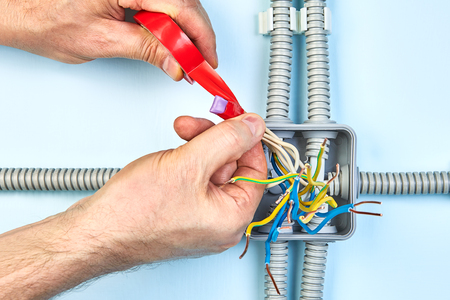

The junction box is a type of electrical enclosure that houses wire splices or branch circuits. They come in various shapes and sizes, usually metal or strong plastic.

These boxes are essential in a building to ensure safety and protect wiring connections. They also allow alterations and repairs to be made.

Safety

A junction box is a crucial part of any electrical wiring system. It protects wire connections from the weather and ensures that people are safe from accidental electric shocks. It also makes it easy to repair any electrical problems that might arise in the future.

These boxes are used in various applications, including in industrial, commercial, and residential buildings. They are usually encased in metal or plastic and come in a variety of shapes and sizes. They are commonly used to house and safely protect hot (black), white, and grounding wires and may include other colors for secondary functions such as lighting.

They are also sometimes used to house cable connections. This is particularly useful when running cables from one place to another, such as from the ceiling to the floor or from an outlet to a wall switch.

It is also often used in swimming pools as the connection point for the cords to the lights and other equipment, helping to prevent electrocution. This is a significant safety concern because it can lead to the death of anyone who comes into contact with the electrical cords.

Similarly, junction boxes are sometimes used in a nuclear reactor to connect the main power circuits. The wiring from the incoming and outgoing circuits must be protected by fireproofing to avoid short circuits in case of an accidental fire.

The type of material used to make the enclosures is an important factor in the overall performance and durability of a junction box. For instance, steel enclosures are a good choice for many applications because they are strong and hard to break down. They also tend to withstand corrosion and water better than most other materials.

Polycarbonate is another common enclosure material that is used for junction boxes. It is also very durable and is resistant to water, making it a great option for outdoor use.

There are many types of junction boxes, but the most popular ones are NEMA-rated terminal box, which means that they can withstand certain environmental conditions. This is especially helpful for manufacturing environments where a lot of pressure is put on the equipment. These enclosures are also ideal for medical facilities, where safety is a top priority.

Space

A junction box is a great way to organize your building's electrical wiring and to protect it from the elements. This helps prevent wires from getting chewed by animals and tripped over by curious humans. It also helps keep a building's power grid free of debris that can cause short-circuits and other issues.

A properly designed junction box can even help you save some money on your energy bills. These enclosures are also designed to withstand high levels of vibration and temperature extremes, which means they'll last longer and save you the cost of having to replace them in a few years.

There are a number of features to look for when selecting an electrical junction box, including the most obvious - how many wires will it accommodate? This information can be gathered by looking at NEC sizing tables that describe how much space each type of connection requires.

The best way to choose a junction box that meets your needs is to take a few things into consideration: the size and material of the enclosure, what you intend to use it for, and the most important factor - where it will be located. You will also want to consider the enclosure's safety rating, which will determine how well it withstands exposure to the sun, weather and other factors.

There are a number of other features to look for in a junction box that are just as relevant to your specific application. A good junction box also features the best material and design for your specific situation, so you can be confident that it will last a lifetime.

Convenience

The junction box is an important component of any electrical wiring project. It helps ensure that the wiring is installed properly and meets the electrical tee box building codes. It also offers a convenient way to make electrical connections and switches.

The box is designed to provide safety and space for electrical wires, while keeping them organized per the building's floor plan. It also prevents tampering with wiring and ensures that fire-related issues are prevented.

Most junction boxes are made of metal or plastic, depending on their capacity and application. Some are designed to withstand heavier loads and support light fixtures. These types can also be covered with protective covers for additional protection.

They are available in many different shapes and sizes, with options to suit all needs and budgets. These include octagon, rectangular, square, and round boxes, as well as specialty designs for special applications.

Unlike block connectors, junction boxes house all the wiring and joins within the box itself, preventing bare wires from being exposed or knocked on. They are also easy to use, with terminals that come with either 3, 4, or 5 holes so that you can connect the cables without the need for any tools.

These are the perfect option for any wiring project, as they offer easy connectivity and maintenance. The terminals are secured to the main housing by screws, ensuring that they are never disconnected during any type of wiring activity.

They are available in a variety of colors to match any existing design. They are also available in a number of different materials, including stainless steel and aluminum.

The convenience of the junction box is a big selling point for many builders and electricians. It can be used for a wide range of wiring jobs, from a small home project to a large commercial facility.

This is why you will see junction boxes outside almost all buildings that have more than one unit of electricity. They are designed to house wires that supply power to almost all of a building.

A junction box is an essential part of any electrical wiring project, and it's a requirement for all commercial and industrial buildings that utilize electricity. It's a good idea to choose a box that can accommodate the total number of conductors and splice points needed for the project. It's also recommended to choose a box that's waterproof and can withstand the elements.

Durability

Keeping your electrical connections and equipment safe from the elements is crucial for safety and reliability. One way to do this is by using a durable junction box, which helps keep your wires and components free of moisture, dust, and other contaminants.

There are several different types of boxes to choose from, and each offers a variety of benefits. However, the best choice depends on what your project involves.

For example, if you’re working in a manufacturing facility that requires tough, corrosion-resistant boxes, you may want to look for NEMA 12 enclosures. If you’re in a more hazardous environment, you might need NEMA 3R or NEMA 4X enclosures.

If you’re installing your junction box in a commercial setting, you might also need a NEMA 6P-rated option. Polycase extension tee box has a wide selection of heavy-duty plastic enclosures that offer the strength you need for commercial applications.

These types of boxes are often used in conjunction with metal conduit. The advantage is that these enclosures have a higher protective rating than many plastic junction boxes, and they also stand up to denting and deformation from impact.

They can also resist rust from many common industrial chemicals. They’re also available in a variety of shapes and sizes.

Another benefit of these types of boxes is that they are typically easy to install in new construction when you’re preparing the wall for drywall. You can install them by simply holding them against the wood framing and driving two nails that come pre-attached to the box.

In addition, plastic junction boxes are often more cost-effective than their stainless steel counterparts. In some cases, they can even be a better choice than aluminum or die cast steel.

Finally, some plastic enclosures can be easier to customize than metal ones. They often feature pre-cut knockouts that are easy to remove with a standard screwdriver, and they can be customized for almost any configuration.

In general, plastic junction boxes are a good choice for indoor applications and are less expensive than many metal options. But they won’t provide the same level of durability that you get from a metal enclosure, and you won’t be able to use them in some installations that require metal conduit.

Comments

Post a Comment