What is the reason for choosing gray cast iron as the material of cast iron platform

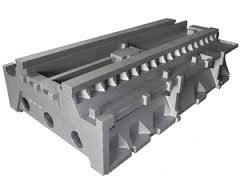

Gray Cast Iron - The Material of Cast Iron

What is the reason for choosing gray cast iron as the material of cast iron? It has many advantages and is widely used in different industries like automobile parts, construction & engineering, valves & piping etc.

The main reason is that the graphite flakes present in the metal make it easier to machine and give it better lubrication and resistance to wear. However, the flakes also allow areas of weakness to develop which can lead to fractures.

Strength

Gray cast iron is a popular material for castings and can be used in many applications. It has a high carbon content, which is one of the reasons it is so versatile. It is easy to cast and machinize, and it is strong and durable.

A common type of gray cast iron contains 2.5%-4% carbon, 1%-3% silicon, and some additions of manganese ranging from 0.1% to 1.2%. Its graphitic microstructure is a key factor in its strength and ductility, but it also has areas of weakness where fractures can occur.

These areas are usually in the graphite flakes that make up the gray iron matrix. The large flakes are more prone to breakage and have less strength than the finer flakes. Inoculants are often added to encourage the formation of smaller flakes.

Another way to increase the strength of gray cast iron is by alloying it with other elements such as copper, nickel, molybdenum, and chromium. These elements help control the matrix microstructure while strengthening the ferrite phase. The tensile strength of alloyed gray cast iron is generally higher than that of as-cast malleable iron, though it is less than steel.

In addition to the chemical composition, foundry practice can have a significant impact on the mechanical properties of cast gray iron. For example, the temperature and cooling rate of the molten iron play an important role in the strength and ductility of gray iron castings.

The amount of nitrogen in the iron can also affect its metallurgy and strength. The presence of nitrogen in the cast iron has been reported to reduce the formation of larger flakes and improve its strength.

There are a variety of molding processes used to produce gray iron castings. The process that is most appropriate for a particular application depends on the design of the casting and the available foundry equipment.

The tensile strength of gray cast iron is typically in the range of 20 ksi to 60 ksi, with higher strengths being used in applications that require higher strength. This can be verified using the Brinell hardness test, which is a standard method of testing iron materials.

Corrosion Resistance

Gray cast iron is a popular choice of material for many industrial applications. It offers several benefits, including excellent machinability and resistance to galling and seizing in sliding surfaces.

In addition to these features, it has a good corrosion resistance. It resists corrosion in most corrosive environments, especially at low temperatures. However, it is not as resistant to H2SO4 as high-si cast iron.

The corrosion resistance of gray cast iron is influenced by both the graphite morphology and matrix structure. The morphology is important in the ability of graphite to act cathodically with the metal matrix, and it also determines the potential for ferrite, pearlite, and cementite formation. The matrix also plays a minor role, though its effect is much less significant than that of the graphite morphology.

Another aspect of corrosion resistance that affects the corrosion behavior of gray cast iron is foundry practice. The cooling rate in the foundry affects the crystalline growth of the graphite flakes during solidification, and this can influence corrosion.

There are different types of graphite in gray cast iron, including ductile, vermicular, A-type and dendrite. The ductile form is the most resistant to corrosion, while the vermicular forms are least resistant.

Moreover, the corrosion resistance of gray cast iron can be improved by alloying with chromium or nickel, depending on the application. This can increase its toughness and tensile strength.

Corrosion rates are generally low, but can rise in marine atmospheres. In this case, the use of a bituminous coating can help to protect against damage from atmospheric attack.

This corrosion resistance is further enhanced by austempering. During this process, the austenite in the ADI is stabilized to form a matrix of ferrite and/or bainitic ferrite. This allows the material to withstand a wider range of temperature and concentrations of sulfur trioxide than traditional non-austempered GCI, as well as offering increased strength and toughness.

In addition to these advantages, gray cast iron is also known for its excellent lubrication and resistance to wear. This is because the flakes in graphite act as an excellent lubricant, and they are also capable of trapping moisture in the air, thereby slowing down the corrosion of the steel.

Workability

What is the reason for choosing gray cast iron as the material of cast iron? This type of iron is characterized by its strength, ductility, and heat-resistance. It can be used for a variety of applications, including machine parts and tooling components.

Its cost-effective ration of machinability to strength makes it an excellent material for industrial applications that require a combination of high strength and durability at a reasonable price. This makes it a great choice for use in the oil and gas industry, construction, fluid power, and heavy equipment.

The workability of cast gray iron can be influenced by many factors, including the amount of tin alloyed in the molten metal. In most applications, a small amount of tin alloy is not required; however, when the casting contains an important section that may be relatively thin or thicker, then more tin alloy must be alloyed with the molten gray iron.

Another factor that influences the workability of gray cast iron is the number density and volume percent of hard inclusions in the casting. These hard inclusions are a significant cause of low machinability in gray iron. This effect can be reduced by reducing the concentration of hard inclusions in the molten gray iron.

In addition to reducing the concentration of hard inclusions in gray malleable iron fittings, the addition of silicon can also improve the workability of this type of iron. In a study on dry sliding wear, the impact strength (I) and fracture toughness of a grey cast iron with different levels of silicon additions were tested at various speeds, load and times.

Results showed that the wear transition occurred at 3.2% silicon addition. It is important for design engineers to note that the wear transition occurred at this concentration, irrespective of the different speed, load and time variations in the test.

The machinability of cast gray iron can be improved by alloying it with other metals such as chromium, manganese, and sulfur. The addition of these metals can help improve the workability of gray iron in a variety of applications, such as cylinder bores, piston rings, and other types of machine parts that are designed for high-speed machining. In addition, these alloys can also be used as grinding media in ball mills.

Durability

Gray cast iron is a common material that is used across many industries and foundries. It is a popular choice for castings due to its low cost and versatility. Despite its popularity, there are a few things to keep in mind when choosing this material for your next project.

One of the most important factors to consider is durability. This will determine how long a casting will last and whether it is worth the money you spend on it.

The most common way to test the durability of a casting is through the Brinell hardness test. This is a specialized compression test that will help you determine the actual hardness of the material. It will also allow you to see how well the material holds up to a high load.

Another important factor to consider is the composition of the metal. It is a good idea to choose gray brass bush that has the appropriate amounts of carbon, silicon, and manganese in it. The amount of nitrogen in the casting is also important because it can affect the strength of the metal.

A higher level of nitrogen in the metal will improve its strength. It will also increase its hardness. However, if this level is too high, it will make the casting unsound.

In addition to the aforementioned properties, gray iron is also known for its resistance to scoring and galling. This can be attributed to the graphite flakes that are present in the material.

These flakes have a flake-like shape that helps to give gray iron its added lubrication and resistance to wear. They also act as stress raisers, which means that they can cause areas of weakness to develop in the metal.

When the metal is weakened, it can fracture, which can lead to a variety of problems. This is the reason that gray iron has low tensile and impact strength.

The hardness of gray iron can also be affected by the amount of manganese and sulfur in the casting. This is a problem that has recently been studied and confirmed by the scientific community. It has been found that when the manganese and sulfur levels in the casting are too high, the iron will have a hard, brittle surface.

Comments

Post a Comment